News

See the latest news stories from Colpac.

Sustainability

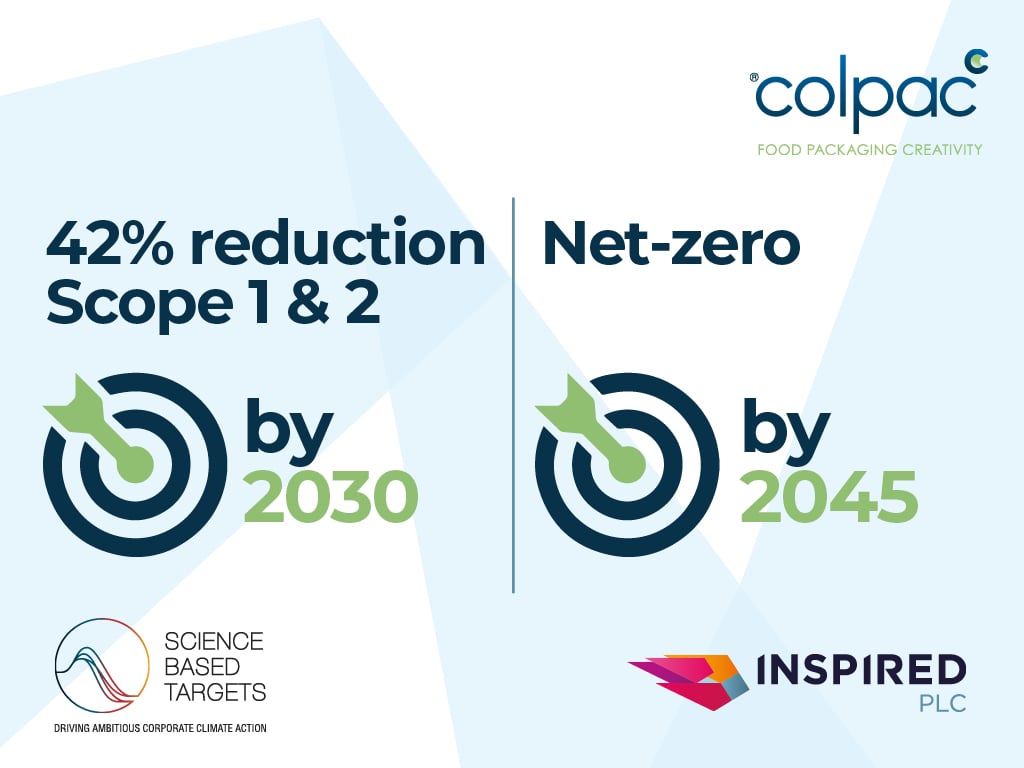

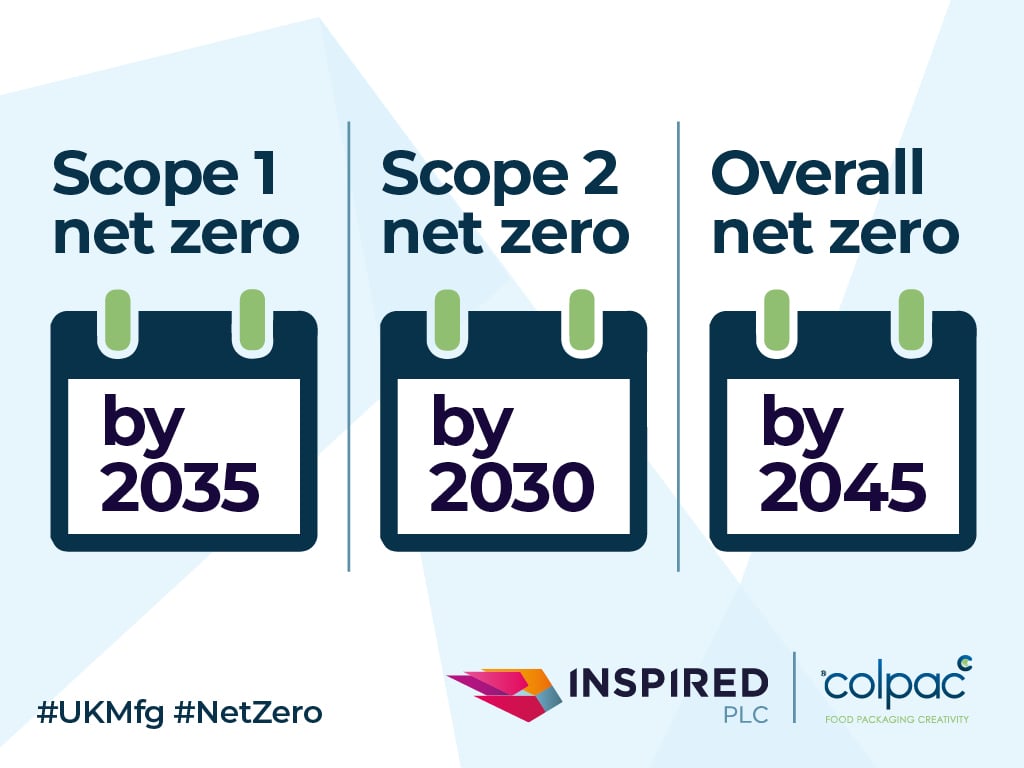

Colpac Releases its First Environmental, Social, Governance Report

Colpac is excited to announce the release of its first Environmental, Social, Governance (ESG) report. Key highlights of the report include details of sustainable sourcing and environmental management, as well as Colpac’s net-zero programme with targets approved by the Science… Read more

1 min read

11th April 2024

Our news & offers

Subscribe today to our newsletter for the latest news and updates about our products and services.